Research Initiative - Litz Hitech Corp.

Design and Development

To ensure that the new products completed in the development meet the market requirements as well as the needs of customers, Litz Hitech has regulated relevant procedures to standardize the product design and development process, effectively mastering the operational progress, controlling the quality of development and assuring the product performance.

Customer satisfaction

- From the product development plan, specifications setup, design operations, prototype machine trial to volume production, the R & D department takes strict control to ensure the product can meet customer needs.

- After the completion of each product, going under the process of design, overall planning design and trial operation, all design verifications and confirmations must be implemented to assure that the new product meets the design input requirements.

- The R&D department has introduced the 3D solid model construction design, greatly reducing the number of model trials, modification time and cost, enabling the product’s look to be confirmed as early as possible; meanwhile, accelerating product launch or delivery time.

Technical indicators

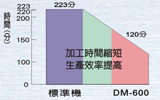

Precision mold processing

Processing engineering: Lamp mold

Materials to be cut:SKD-61

Materials to be cut: 92 x 50 x 35mm

Dry cutting

Cutting conditions (standard machine)

Cutting conditions (DM-600)

Fine pore processing

Drilling diameter:¢0.15m/m

Number of drilling holes:497 holes

Board thickness:1m/m

Cutting conditions

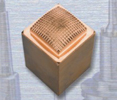

Precision processing

Processing engineering:Engraving copper pole

Materials to be cut:copper

Dimension of materials: 35 x 35 x 35mm

Dry cutting