Quality Assurance - Litz Hitech Corp.

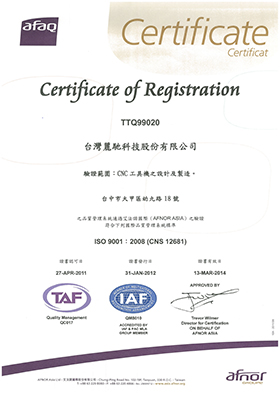

The unremitting pursuit of precision and quality is a feature of Taiwan Litz, and is also a characteristic of each employee of Taiwan Litz. We have been holding this spirit and manufacturing high-performance products verified by ISO 9001 certification which serves a fundamental guarantee for excellent workmanship, products and services.

Certified by ISO 9001

|

Certified by ISO 14000

|

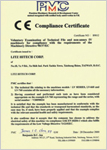

Certified by CE

|

|

Certified by EMC

IQC

For each group of zero cotton, precision gauges must be inspected before assembly to ensure the precise quality of the parts. Inspection records need to be fully recorded in the process for future tracking services.

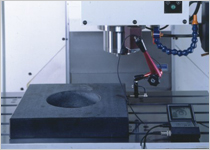

Precision parts are measured on a granite platform using a secondary element bed.

The inner diameter of the casing and the inner diameter of the precision cylinder gauge. .

Precision parts are measured on a granite platform using a secondary element bed.

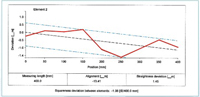

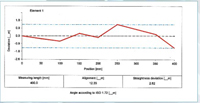

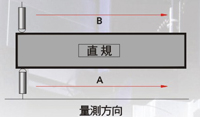

Two rails parallel measurement

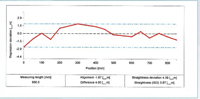

Track straightness measurement

|

|

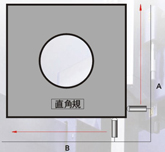

straightness and squareness measurement

|

|

squareness measurement

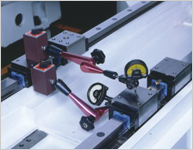

- The two axes are read by the probe, and after entering the TT10 instrument, a curve is created to obtain the error and relationship between true straightness and straight angle.

|

|

straightness measurement

|

|

|

|

Advanced inspection equipment and technology

In order to ensure maximum product quality and meet customer needs, Litz develops a complete quality control system and uses advanced inspection equipment and technology to ensure product quality.

Laser inspection

- The full travel accuracy is compensated by the laser correction to ensure the precision and calibration results of the machine.

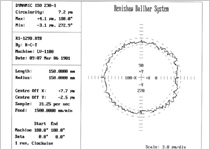

Circular inspection

- Use circular measuring instrument to correct the true circular precision and the machine geometrical accuracy so as to ensure the movement accuracy of the three-dimensional space of the machine bed.

Spindle dynamic balance correction

- The IRD dynamic balance device is used to correct the speed, displacement and acceleration characteristics of the maximum spindle speed.

Pulling force test for spindles

|

|

Balance correction for spindles

|

|

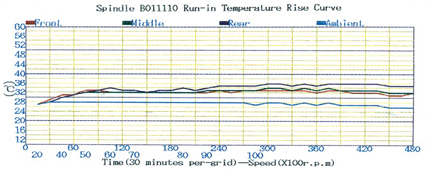

Temperature rise and run test for spindles

- After the main shaft assembly is completed, the temperature rise and run test for spindles are performed through the computer running program.

- Each spindle detects its temperature through multi-point temperature sensors. The rotation speed changes from low to high to ensure that the spindle gets the best running-in.

Reference block test

- Each machine must be tested and tested by precision instruments, and dynamic cutting tests must be done in accordance with international standards.

- The standard test blocks that have been cut are subject to three-dimensional bed testing to ensure that the accuracy meets the standards.

Exquisite scrapping and craftsmanship

With exquisite scrapping technology, the contact surface of the slideway is carefully crafted, and the precision lasts longer.

Nut base accuracy is calibrated to ensure transmission accuracy.

After each machine is scratched, it is checked by rubbing, and the job records are saved.

The special oil circuit design provides enough lubricant for the slide surface to ensure the transmission accuracy.

VDI 3441 positioning and repeatability (positioning precision) chart

|

|